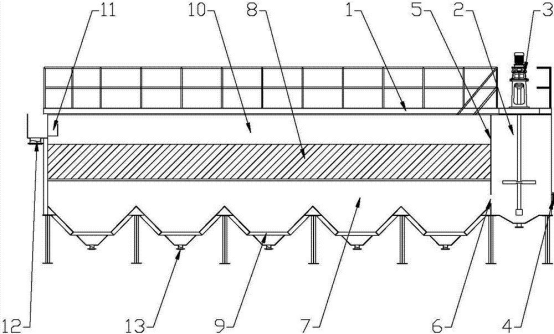

Lamella clarifier is also called lamella separator and inclined plate water clarifier, is one kind of high efficiency solid-liquid separation sedimentation tank which works on shallow tank theory to remove solid particles from liquids.

Specifications:

Capacity: up to 350m3/h

Dimension: Customized

Material: Carbon steel, FRP or stainless steel